Solderless LED Rigid Bar 12V/24V 1.5W/led led roller strips

Solderless Welding-free rigid led light bar 12V/24V 1.5w/led Led Roller Strip for Built-in backdrops, backlit light boxes and flexible film ceilings

The solder-free design simplifies operation, improves reliability and reduces costs, solving customers' core pain points in installation efficiency, maintenance costs and material waste, while creating higher market premiums and customer loyalty for enterprises. This design will become a key technical point for differentiated competition in the field of commercial and advertising lighting.

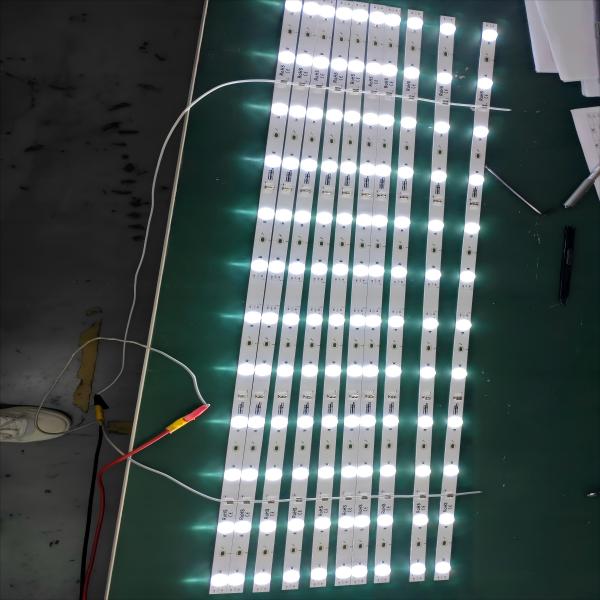

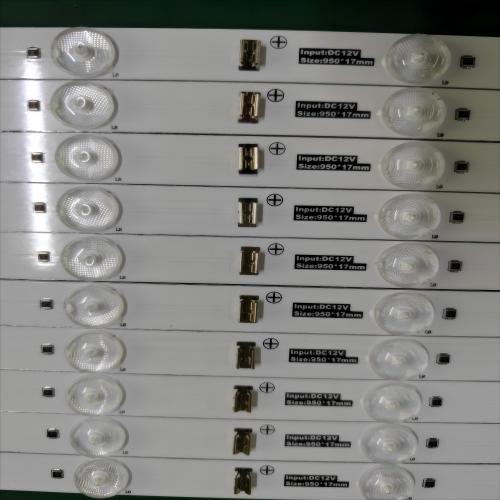

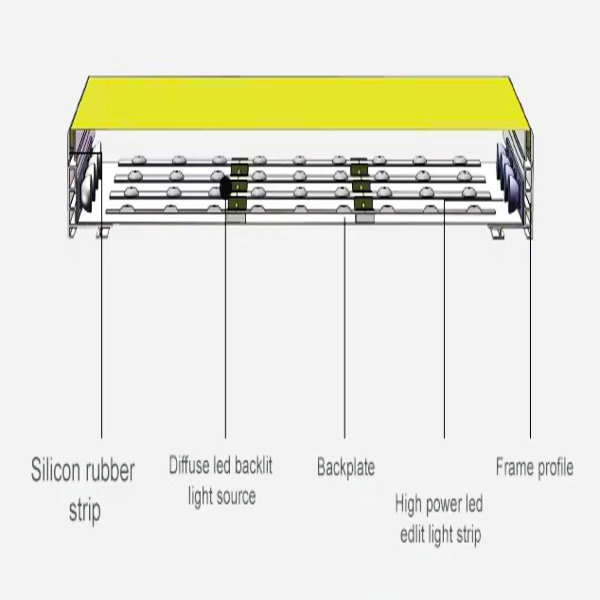

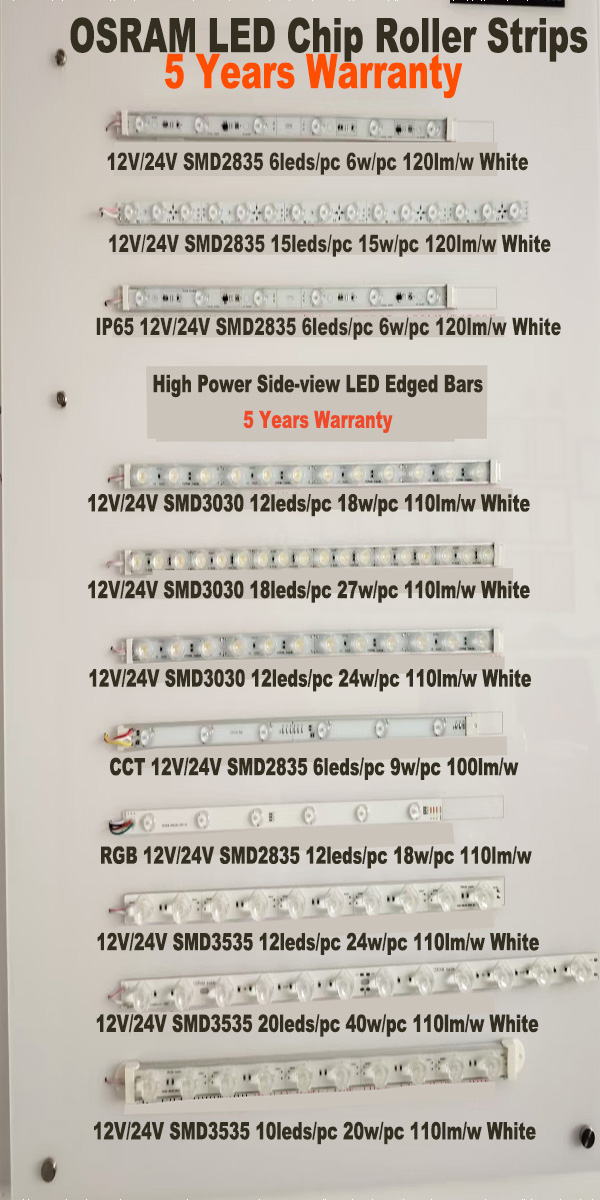

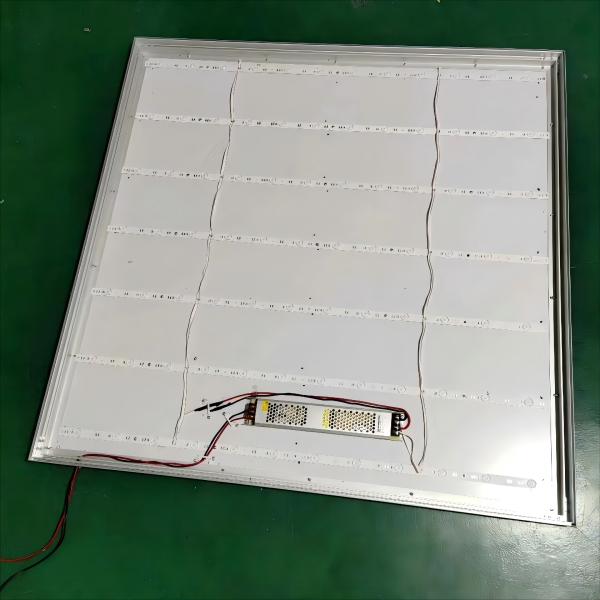

We offer a variety of led roller strip lamp bead chips, including SMD2835, SMD3030, and SMD5730.The standard lengths of roller shutter light strips are 50 centimeters (6 LEDs/pc), 90 centimeters (12 LEDs/pc), 100 centimeters (14-16 LEDs/pc), and 120 centimeters (18-24 LEDs/pc). Each roll-up light strip contains 20 to 40 light strips. Its primary advantage is that the spacing of light strips can be adjusted according to the thickness of the light box. Through a parallel circuit, it ensures no voltage drop, fast installation, and high-efficiency lighting.LED roller strips have become the mainstream choice of light source for advertising light boxes. Its modular design, energy-saving and environmentally friendly features, and scene-adaptive flexibility make it a popular choice.

The LED Roller Strip features a thickened aluminum substrate bottoming, waterproof and flame retardant ABS bottom groove, acrylic material covering, diffuse reflective lamp bead design, and high-brightness brand lamp beads (Coretronic chip, OSRAM chip, Epistar chip, etc.). It is also equipped with pure copper connecting wire.We have 6leds/pc, 12leds/pc, 20leds/pc for your choice. They are mainly used in outdoor patio lighting, landscape lighting, built into indoor and outdoor escalators or outdoor patio lighting, bedroom, bar lighting decoration, etc.

Specification:

| Item No. | MS-SRS2835-15W | MS-SRS2835-18W | MS-SRS2835-27W | MS-SRS2835-36W |

| Voltage | 12V/24V | 12V/24V | 12V/24V | 12V/24V |

| Wattage | 15W | 18W | 27W | 36W |

| Efficiency | 110lm/w | 110lm/w | 110lm/w | 110lm/w |

LED Quantity | 10leds/pc | 12leds/pc | 18leds/pc | 24leds/pc |

| Size | L72*W13.5*H9cm | L92*W13.5*H9cm | L108*W13.5*H9cm | L124*W13.5*H9cm |

Color | Warm white,Natural white,Cool White,Red,Green,Blue | Warm white,Natural white,Cool White,Red,Green,Blue | Warm white,Natural white,Cool White,Red,Green,Blue | Warm white,Natural white,Cool White,Red,Green,Blue |

CRI(Ra) | >90 | >90 | >90 | >90 |

| UGR | ≤16 | ≤16 | ≤16 | ≤16 |

| Warranty | 3/5 Years | 3/5 Years | 3/5 Years | 3/5 Years |

Features:

Low voltage, safe LED strip. DC12V/24V;

Aluminum PCB dissipate heat quickly;

Patent-design connect,wire length is adjustable;

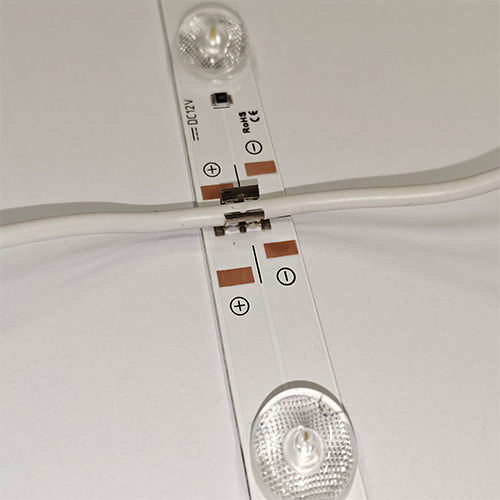

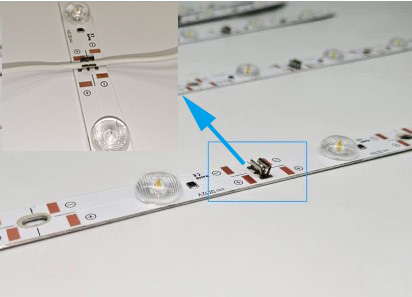

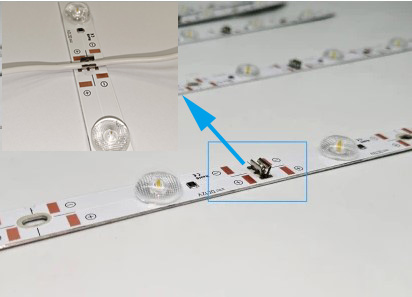

Solder-free design (plug-in terminal wire, magnetic interface and crimp connector):

(1)Simplify the installation process, reduce time and labor costs: Traditional welding requires professional tools and skills, and also requires multi-person collaboration, which takes 2-3 hours/10 meters of light strips; the welding-free design realizes "plug and play" through standardized interfaces, and one person can complete the wiring and installation within 1 hour, saving more than 50% of the installation time.

(2) Avoid welding defects and reduce maintenance costs: The welding points of traditional welding are prone to oxidation and looseness, causing the lamp beads to flicker or go out, and traditional welding is prone to poor welding, resulting in cold welding and desoldering; the welding-free design can eliminate such hidden dangers, reduce the failure rate by 70%, and improve product reliability.

(3)Support flexible maintenance: If a section of the light strip is damaged, there is no need to disassemble it as a whole, just replace the corresponding section directly. Welding-free supports precise cutting, reducing scraps by 40%

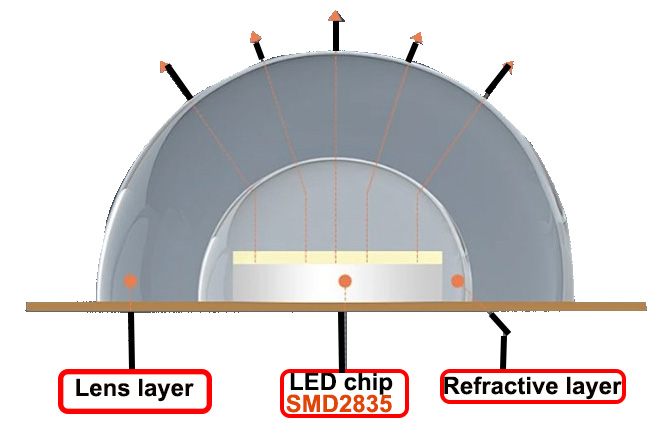

Diffuse reflection design: (1)The lamp bead features a PMMA optical lens with a nano-diffuse reflection coating that scatters light into a 175-degree wide-angle beam. This innovative feature addresses the challenges of uneven illumination and high energy consumption typically associated with traditional lighting solutions.

(2) It also prevents glare and eliminates the direct light spot of traditional light beads, ensuring a uniform brightness in advertisements and preventing visual fatigue among audience customers.

The roller strip utilizes a "parallel circuit + curtain layout," similar to blinds, offering flexible spacing to accommodate varying thicknesses of the light box.

Cut length: 1 led unit(12V); 2 leds unit(24V).

(1) Cuttable design allows customers to adjust the length freely according to the size of the actual light box or display area, reducing the waste of edges;

(2) the cuttable design make strips does not require complex wiring, and can be fixed directly with magnetic suction and adhesive backing;

(3) if part of the roller strip out of the line is damaged, it does not need to be disassembled as a whole to replace it, reducing the cost and time of maintenance.

This design is designed for irregularly shaped advertising lighting fixtures.

Usually the index is greater than 85, closer to the original color of the lighting objects, the color is more vivid.

Multiple colors to choose from: Warm white (2700-3500k), Positive white (4000-5000k), Cool white (6000-10000k), Red, Orange, Yellow, Green, Blue, Purple, Pink, Lemon Yellow, Ice Blue and Pinkish and more;

Low power, high luminous efficiency (100lm/w-180lm/w), even illumination, energy saving;

Easy to install and store, with 3M self-adhesive tape or magnetic suction;

Can be used and stored at temperatures from -40 ℃to 60℃, with a service life of more than 50,000 hours;

Protection level: indoor IP20, outdoor IP65-IP68.

Applications:

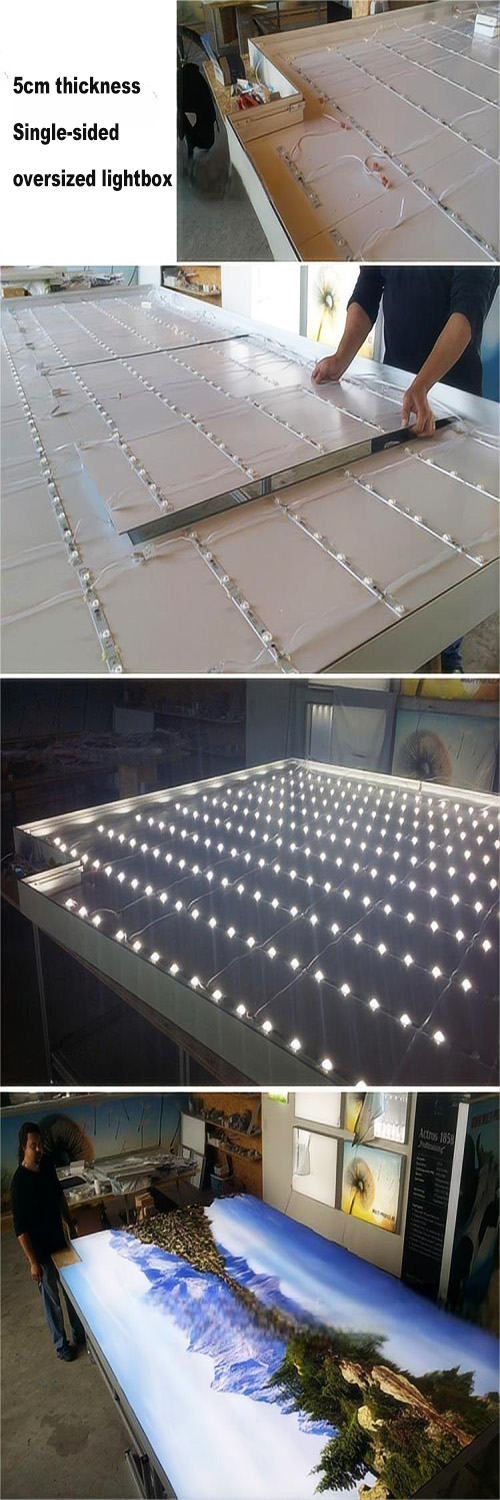

Sign light boxes,Double-side signboard Stairway and walkway lighting, Internally lighted billboards, indoor or outdoor sign cabinets;

2. 3cm-8cm [5.51~15.75in] depth double-sided and 8~20cm [3.15~7.87in] depth single-sided edge lighting light boxes;

3. General lighting, task lighting, household appliances, architectural lighting,Bar Top Lighting;Accent Lighting;Club Lighting;TV back Lighting, villa, restaurant, hotel, meeting room, show room, shop, counter.

Installation:

1. Ensure that the correct DC voltage is supplied and distinguish between positive and negative; in general, the gray (red) wire is positive and the white (black) is negative.

2. Avoid short circuits by following the above connections.

3. Make sure the wires are securely connected. It can be pulled by hand and not moved.

4. Do waterproof treatment and anti-corrosion treatment before wiring.

5. Make sure the connection and installation are good before turning on the light.

6. Do not use chemical solvents in the environment.

7. Close the box for up to 4 hours when fixing with neutral glass adhesive.

8. Connect the end of the wire to the mains cable and ensure that it is treated against water and corrosion.

9. If you want long wires, use 18AWG wire.

FAQ

1.Can I have a sample for test?

Yes, samples are available. We will offer the sample of LED roller strip light for 1 to 20 pcs, and the sample could provide for customer with free, but the freight will be covered by customer account. The sample freight will be returned to customer account after our cooperation.

2.How about the lead time?

Usually we had material in stock, regular order delivery time 1--5 days after the order (Pl) paid. Custom products 8--15 days(Custom PCB).

3.How do you ship the goods and how long does it take to arrive?

We usually ship by DHL, UPS, FedEx. It usually takes 3-7 days to arrive. Airline and sea shipping are also optional.

4.Do you accept OEM service?

Yes, we accept OEM order. we will produce the products as your requirement.

5.ls it Ok to print my logo on product and package?

Yes, it is OK. Before our production, please inform us formally, and confirm the design firstly based on the sample that we send to you.

6.Do you accept the third party inspection?

Yes absolutely we accept.

7.How to precede an order for led roller strip light?

Firstly let us know your requirements or application.

Secondly we quote according to your requirements or our suggestions.

Thirdly customer confirms the samples and places deposit for formal order.

Fourthly we arrange the production once the payment received.

Finally, once finish production, we will arrange shipment and send the track Number with no delay.

8.How much tax should I pay for custom when we buy goods from you?

Different country had different import policy: you need to figure out with Custom, We don't have a exact answer about this. but most of country 25% on the invoice value.

9.What after-sale services does your factory offer?

Our factory offers free technical support, and we will provide replacement and refund service if any product problem.