What are the main components of LED Flexible Strips?

What are the main components of LED Flexible Strips?

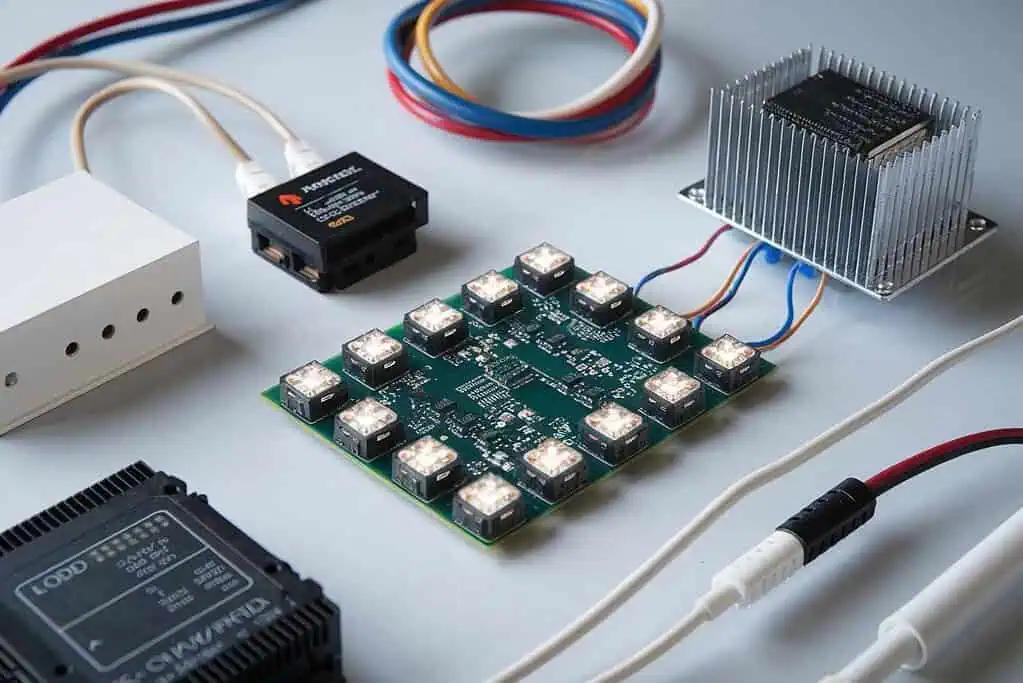

LED Strips consists of several components such as LED chip, LED driver, PCB, optics, heat sink, LED controller and so on. All these components work together to ultimately produce light output. Any defects in these components will affect the performance of the lamp. Therefore, it is vital to understand the standard and quality of LED components.

Firstly, what is LED?

LED stands for "light-emitting diode." An LED is a semiconductor that emits visible light when an electric current is passed through it. This semiconductor emits visible light when an electric current is passed through it.LEDs, short for "light-emitting diodes," are designed to follow the principle of electroluminescence, which involves the emission of light when an electric current is applied. During this process, the electrons and holes in the semiconductor recombine when exposed to an electric current. This process releases energy in the form of photons, which we perceive as visible light.

However, the color of the emitted light depends on the amount of doping and the type of semiconductor. For instance, blue and white LEDs utilize gallium nitride (GaN), while green and yellow LEDs employ gallium phosphide (GaP) as the semiconductor.

Secondly, what are the primary components of LED lighting systems?

1. Printed Circuit Board

Printed circuit boards (PCBs) are the substrates on which LEDs are soldered and electrically connected. The materials used in their construction include FR4, copper, aluminum, screen printing, resin, and glass. PCBs are available in various shapes and sizes, depending on the LED application. For instance, LED light strips utilize thin, flexible PCBs that can be bent and cut to size. Conversely, rigid PCBs made of FR4 are utilized for fixtures such as LED tubes or LED panel lights.2.LED Chip

LED chip is the main component of LED lamps and lanterns to emit light.LED chips come in different sizes and packages. According to different technologies and packages, LED chips can be categorized as follows:

(1) SMD LED

Surface Mount Devices (SMD LEDs) are small LED chips mounted directly on the PCB. These LED packages are used in LED strips, TVs, monitors, etc.The brightness of SMD LEDs varies with different shapes and sizes. They are denoted by numbers such as SMD2835, SMD3528 or SMD 5050. The first two digits of the number indicate the width of the LED, and the last two digits indicate its length. For example, SMD3528 means that the width of the LED is 3.5 mm and the length is 2.8 mm.

(2) COB LEDs

Chip-on-Board (COB) is a lighting technology that tightly packages LEDs on a single circuit board to create a smooth design. Unlike SMD LEDs, COB LEDs do not have any visible gaps between them. As a result, it is free from hot spots and provides smooth, continuous illumination.Because COB LEDs are packaged in a high-density package, the illumination is brighter. As a result, COB is ideal for applications that require a more focused, seamless light output.

(3) CSP LEDs

Chip-Scale Packaging (CSP) is a new LES packaging technology designed for compact, high-performance lighting. The size of these LED packages is comparable to the LED chip size. CSP LEDs are widely used in LED strips, downlights, panel lights, automotive lighting (headlights, taillights, etc.) and more.Now you may confuse COB and CSP as they are both designed for high density.CSP is more compact than COB as these chips are packaged in a compact package and do not take up any extra space on the PCB. They also have better color consistency than COBs. However, in terms of brightness, COB LEDs are designed for a higher lumen output. Therefore, if you need high brightness, choose COBs; for compactness, CSPs are a better choice.

(4) Mini LEDs

Mini LEDs are a type of high-tech LEDs designed for small chip sizes (less than 0.2 mm in size). These Mini LEDs are used in displays, especially TVs, tablets and laptops. In fact, Mini LEDs are a bridge between traditional LEDs and Micro LEDs. They are brighter, have higher contrast and are more energy efficient.3.Power supply

Power supply is the main component of LED fixture to supply power to LEDs. It converts the AC power from the mains to the DC power required by the LEDs. There are the following types of LD power supplies:

(1) Constant Current (CC) Power Supplies

Constant current power supplies keep the current output constant; however, the voltage varies according to the LED load. They prevent LED damage by preventing current fluctuations. Constant-current power supplies are used for high-power LEDs or fixtures with multiple LEDs in series. For example, COB LED strip lights and high-power downlights use these power supplies.(2) Constant Voltage (CV) Power Supplies

Constant voltage power supplies are used for low voltage applications such as LED strips. These power supplies provide a constant voltage output, such as 12V or 24V, allowing the current to vary according to the load.(3) Dimmable Power Supplies

Dimmable power supplies have built-in dimming technology such as TRIAC, PWM (Pulse Width Modulation) or 0-10V dimming. You can adjust the lighting intensity according to your mood or comfort level.(4) Plug & Play Power Supplies

Plug & Play Power Supplies are designed for low-power LED applications such as LED strips, table lamps and decorative lights. For example, 5V USB-powered LED strips use this plug-and-play adapter. Plug and Play power supplies are very easy to connect. These Plug & Play power supplies are equipped with a standard plug and built-in transformer, eliminating the need for wiring.4. LED Drivers

LED drivers regulate the voltage and current of LED lighting to ensure its safe operation. LED drivers are usually interchangeable with power supplies, but there are significant differences between them.AC/DC power supplies can provide a variety of voltages for household appliances. On the other hand, an LED driver is specifically designed to regulate the power of LEDs. It maintains the desired voltage and current of the LED by preventing voltage and current fluctuations.LEDs that hum or flicker are caused by LED driver failures.

5.LED CONTROLLER

LED controller can be used to regulate the light intensity, change the light colour, effects and so on. Depending on the lights you use, the type of LED controller may vary. The following are common LED controllers:(1) PWM LED Dimmer

PWM stands for Pulse Width Modulation. It dims the light by flashing at a pulse frequency that is imperceptible to the human eye. You can't see the light flicker, but rather feel the light dimming. However, the camera can detect this flicker; this is why PWM LED dimmers are not suitable for photographic applications.(2) Infrared LED Controllers

Infrared LED controllers use infrared (IR) signals to control LEDs. These controllers are affordable and easy to configure. IR LED controllers are primarily used for basic indoor lighting control. Although they do not use infrared (IR) signals to control LEDs, they support very short distance control. In addition, the controller and the fixture must be in face-to-face contact to transmit the IR signal.(3) RF LED Controllers

Radio Frequency (RF) LED controllers are medium distance controllers. Unlike infrared LED controllers, RF does not require direct visual inspection; it can pass signals through walls or other objects. Therefore, RF LED controllers support long distance communication.(4) Wi-Fi LED Controller

Wi-Fi LED controller uses Wi-Fi signals to control lights via mobile phones, remote controls or any wireless devices. It provides wide lighting control area. Easy to operate, you can control the lights from an app on your smartphone. It also offers smart features such as voice control.(5) Bluetooth LED Controllers

As the name suggests, these controllers use Bluetooth signals to connect to the lights. They are easy to install and can be operated from a smartphone. However, Bluetooth LED controllers have limited coverage compared to Wi-Fi LED controllers.(6) 0/1-10V LED Controller

This is an analogue LED controller that controls the brightness of LEDs by adjusting the voltage between 0/1 and 10V. When the voltage is 10V, the LED brightness reaches 100%, while when the voltage is 0/1V, the brightness is reduced to a minimum. These controllers do not require any additional switches. In addition, the RGBW 0/1-10V LED controllers have full touch control. Each RGBW controller offers fast colour adjustment, brightness control and a wide range of styles and effects.(7)DMX LED Controller

The Digital Multiplexing or DMX LED Controller utilizes the DMX512 protocol to manage LED lighting systems. This controller allows users to manage multiple LEDs in a single unit. In addition to adjusting the brightness, it facilitates color changes to the light, pre-programmed light shows, custom scenes, and dynamic effects.

The DMX LED controller provides multi-channel control, operating monochrome, RGB, RGBW, and even addressable pixel LEDs.These LED controllers are primarily used for stage, theater, and other professional lighting applications.

(8)DALI LED controller

DALI stands for "Digital Addressable Lighting Interface." It facilitates bidirectional communication, enabling the control of multiple LEDs from a single source. While it is priced higher than some options, it provides superior control of lighting system automation in residential and commercial spaces. Additionally, it can be integrated with building security management (BSM) for centralized lighting control.

6.Heat sinks

Despite their low operating temperature, LEDs can overheat due to voltage overload or insufficient ventilation. To ensure the safe operation of LEDs, heat sinks are mounted on the PCB to dissipate heat. In this way, the LEDs are kept at a low temperature, preventing overheating and protecting the LEDs from damage.

7. Housing or casing

The housing or lampshade is a protective enclosure. It wraps around the LEDs and other electronic components, preventing them from coming into contact with dirt, dust or moisture. Depending on the application of the lamp, the shell can be made of different materials.

8. Optics

The optics is a small domed structural cover directly above the LED. It is made of shatterproof plastic and ensures that the illumination is correctly orientated. Optics include primary and secondary optics.

The primary optics encapsulate the LEDs and provide the basic direction of light. The secondary optics are responsible for optimising the light beam and cover the lens, reflector and diffuser. Lenses are used to focus or diffuse the light. Reflectors, on the other hand, are used to change the direction of stray light to improve luminous efficacy, such as in floodlights and headlamps.LED diffusers are used to reduce glare and produce an even light effect. Diffusers are available in various types: clear, frosted and opalescent.

Optics are a key component of LEDs as it affects the angle of the light beam. Optics such as lenses, mirrors and diffusers adjust the beam to produce a narrow, medium or wide beam pattern.

9.Wires

LED lighting uses different types of wires. These wires are used to connect lights to a power source or to connect one light to another. The following are the types of wiring commonly used in LED lights:

(1) Connection Cords

Connection cords connect LED lights to a power source. These wires are usually made of copper or aluminum with PVC or Teflon insulation for safety. The most common types of connection cords include single-core cords for simple circuits, multi-core cords for applications that require multiple connections using the same cable, and flex cords for applications that require wire flexibility or mobility.

(2) Lighting Connectors

Lighting connectors are used to connect multiple lights together. For example, LED strip connectors are used to connect multiple LED strips together. Depending on the type of LED strip, these connectors are available in 2-pin, 3-pin, 4-pin, 5-pin, and 6-pin types. For example, 2-pin LED strip connectors are used for single color LED strips and 4-pin connectors are used to connect RGB LED strips.

(3) Wall Plug Power Cords

These cords connect LED lights to a wall outlet. Depending on local standards, these power cords are available with either two- or three-prong plugs.

Thirdly, it is essential to understand the functionality of LED components.

First, the power supply current flows through the LED chip. The semiconductor material inside the chip generates light through a process called electroluminescence.The optics then direct and focus the emitted light to form the desired beam pattern according to the needs of the application. To ensure proper and efficient operation of the LEDs, the LED driver regulates voltage and current. This allows for optimal performance.A heat sink in the LED light dissipates the heat generated, thereby keeping the LEDs cool.

The housing or casing provides essential protection for all components, acting as a shield against potential damage. This feature effectively prevents air, moisture, and dust from entering the LED, ensuring optimal performance and longevity.

How to choose LED ceiling lighting: A comprehensive guide to LED soft ceiling lighting solutions

How to choose LED ceiling lighting: A comprehensive guide to LED soft ceiling lighting solutions

What is the best solution for a thin lightbox with regard to the "rib pattern" issue that has been reported for AC110V/220V diffused roller light strips?

What is the best solution for a thin lightbox with regard to the "rib pattern" issue that has been reported for AC110V/220V diffused roller light strips?

Case Study: An analysis of the practical impact and customer feedback regarding AC110V/220V diffused rigid light strips when implemented in the exterior wall application of large shopping malls.

Case Study: An analysis of the practical impact and customer feedback regarding AC110V/220V diffused rigid light strips when implemented in the exterior wall application of large shopping malls.

Why do we recommend you 220V welding-free diffused roller rigid light strip for commercial high-end lighting?

Why do we recommend you 220V welding-free diffused roller rigid light strip for commercial high-end lighting?