Why do we recommend you 220V welding-free diffused roller rigid light strip for commercial high-end lighting?

Why do we recommend you 220V welding-free diffused roller rigid light strip for commercial high-end lighting?

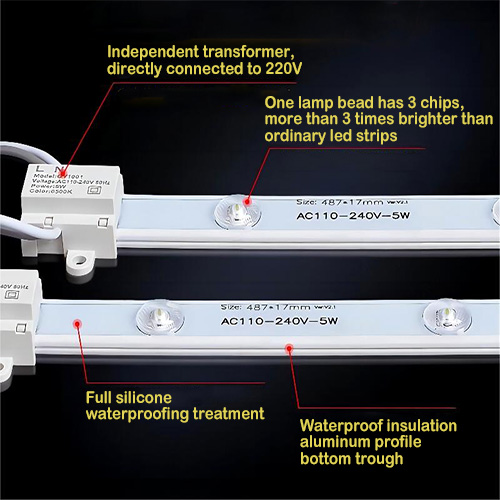

The core value of the AC110V/220V rigid light bar lies in simplifying power supply, reducing costs, and improving installation efficiency. Designed specifically for the specific needs of advertising light box lighting, it connects directly to the mains (110V/220V AC) to simplify system structure and optimize costs. It addresses the high brightness and long-distance power supply requirements of large light boxes, making it particularly suitable for outdoor applications with limited budgets and controllable safety requirements.

Firstly, let's review the design rationale.

1. Simplified power supply system.

AC110V/220V diffuse roller light strips can be directly connected to the mains, eliminating the need for a separate 12V/24V power adapter and reducing power conversion steps. This approach offers a dual benefit of reducing component costs and eliminating the potential for maintenance issues caused by power failures. For instance, low-voltage light strips necessitate a dedicated power supply (100pcs light strips require a power supply of 60W or more), while high-voltage solutions eliminate this step.

2. Reduced voltage drop over long-distance transmission.

In large light boxes (such as outdoor billboards), low-voltage light strips are prone to voltage drop due to line resistance, resulting in reduced brightness at the end. The 220V solution significantly reduces the impact of voltage drop by reducing current through high voltage, ensuring uniform brightness across the entire light box.

3. Cost Optimization

Eliminating the power adapter contributes to cost reductions. For instance, the high-voltage solution reduces overall costs (including power supply costs) by approximately 30% compared to the low-voltage solution for 100 light strips.

Secondly,what are the advantages of this product in comparison to low-voltage light strips?What is the potential profit margin for customers?

1. Installation Complexity and Efficiency Issues

Traditional low-voltage light strips require separate wiring and power supply installation, which can be a cumbersome process. AC100V-240V diffused roller light strips feature a parallel design, enabling swift wiring via a mainline connection. This reduces installation time by over 50%, making them ideal for projects with tight deadlines.

2. High Brightness Requirements for Outdoor Use

AC110V/220V diffused rigid light strips offer higher power consumption (60-100W per square meter) and can reach brightness levels of 4000-5800 LUX, far exceeding the brightness levels of low-voltage light strips. These products are well-suited for applications that necessitate high-intensity illumination to attract attention, such as subway stations and shopping mall exteriors. For instance, outdoor advertising light boxes frequently utilize AC110V/220V rigid light bars with high-brightness SMD5730 LEDs to ensure optimal daytime visibility.

3. Space and Maintenance Limitations

In narrow or sealed light boxes (such as blister light boxes), additional power supplies take up space and hinder heat dissipation. The 110V/220V solution requires no power supply, saving space and reducing the risk of overheating. Maintenance only requires checking the light strip itself, eliminating the need to inspect the power module, making fault location faster.

Thirdly, Precautions and Limitations

1. Safety Hazards

110V/220V is a hazardous voltage. Professional installation procedures (such as insulation treatment) are required to avoid the risk of electric shock or short-circuit fire. For humid environments (such as canopy light boxes), it is recommended to switch to a low-voltage solution or enhance protection.

2. Lifespan and Stability

High-voltage light strips have a lifespan of approximately 30,000 hours, lower than the 30,000-50,000 hours of low-voltage light strips. Mains power fluctuations can easily damage the lamp beads, resulting in poor stability.

3. Application Limitations

Low-voltage diffuse reflective rigid light strips are recommended for thin indoor light boxes (thickness <8cm) to avoid the "rib pattern" (shadow streaks) caused by high-voltage light strips at close range.

In summary: The core value of AC110V/220V diffuse reflection rigid light bars lies in its ability to simplify power supply, reduce costs, and improve installation efficiency. They address the high brightness and long-distance power supply requirements of large light boxes, especially in outdoor applications with limited budgets and controllable safety requirements. However, in scenarios involving long-term use of light boxes, the lifespan and safety risks must still be balanced.

How to choose LED ceiling lighting: A comprehensive guide to LED soft ceiling lighting solutions

How to choose LED ceiling lighting: A comprehensive guide to LED soft ceiling lighting solutions

What is the best solution for a thin lightbox with regard to the "rib pattern" issue that has been reported for AC110V/220V diffused roller light strips?

What is the best solution for a thin lightbox with regard to the "rib pattern" issue that has been reported for AC110V/220V diffused roller light strips?

Case Study: An analysis of the practical impact and customer feedback regarding AC110V/220V diffused rigid light strips when implemented in the exterior wall application of large shopping malls.

Case Study: An analysis of the practical impact and customer feedback regarding AC110V/220V diffused rigid light strips when implemented in the exterior wall application of large shopping malls.

Why do we recommend you 220V welding-free diffused roller rigid light strip for commercial high-end lighting?

Why do we recommend you 220V welding-free diffused roller rigid light strip for commercial high-end lighting?